Compliance Garment that meets the

IEST-RP-C003.4

Our Cleanroom garments are specifically designed and manufactured from a range of conforming Cleanroom/ESD fabrics that meets the IEST-RP-C003.4. With many years of designing and sewing experience, we have Cleanroom garments that can conform to ISO 4 requirements. The range of design provides head-to-toe coverage in various combinations such as, jumpsuit, smock, hood, sleeve cover, booties, and other accessories that suit all Cleanroom environments. With the latest edition of laser cutting machine to ensure minimum particulation after wash that gives you total peace of mind.

Overview

The Composition and Structure of Cleanroom Garments

The most recent IEST-RPCC003.4, Garment system consideration for cleanrooms and other controlled environments standard lists six types of nonwoven fabrics for use in cleanrooms and other controlled environments, and describes each fabric as follows ;

Spunbonded or Thermal Bond

A non-woven fabric typically made from polychloroprene in a relatively open structure. More commonly used in bouffant caps, shoe covers etc. This type of non-woven fabric does not demonstrate high barrier performance.

Spunbonded/melt blown/spunbonded (SMS)

A laminate structure made from polypropylene continuous fibres, SMS offer barrier protection and comfort.

Flash spun

A nonwoven fabric made of high-density polyethylene continuous fibres. Flash spun non-woven have some barrier properties and are splash-resistant to water.

Film Laminate

A spunbonded layer laminated to nonporous films. Demonstrates particle, blood and chemical barrier properties but lacksair and moisture permeability.

Melt Blown

Made from continuous polypropylene microfibres and used in composite structures of many types of face masks because of its high filtration efficiency and repellence. Melt blown fabric does not have adequate strength to be used alone for garments.

Microporous film laminate

A laminate made from a spunbonded layer and a microporous film for improved barrier properties. This laminate is a splash-resistant and a blood barrier. Microporous film laminate is optimal for use in surgical areas and critical environments.

When selecting garments for cleanroom use, depending on the specific application, the IEST standard recommends evaluating the fabric properties including testing for (selecting those relevant to the fabric type);

- Cleanliness and cleanability

- Electrostatic properties

- Biological properties

- Durability

- Comfort

- Opacity

- Particle filtration efficiency

- Microbial penetration

- Chemical compatibility

- Fluid resistance

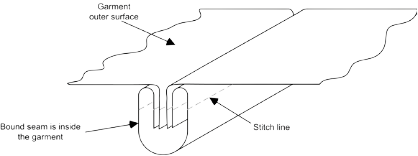

Construction of cleanroom garments is another important consideration, and the IEST standard outlines recommendations for thread and seam structure. Seams for cleanroom garments should be joining seams to avoid free-air/particulate passage from the inside of the garment to the outside environment. The IEST standard recommends for the construction of cleanroom garments that they are constructed using a bound joining seam, as showed below

Ultra Shield

(Material : 168G/133G Series)

Cleanroom Polyester Fabric

Features

- Suitable for cleanroom class 10 garment and shoe

- Good filtration efficiency

- Good ESD performance

- Durable, giving long service life

- Non-lint fabric made of 100% multifilament yarn

- Densely woven barrier fabric

Ultra Shield Plus

(Material : 168G/133G Series)

Cleanroom Polyester Fabric

Features

- Suitable for cleanroom class 100 - 1000 garment and shoe

- Good filtration efficiency

- Good ESD performance

- Washable & reusable

- Durable, giving long service life

- Non-lint fabric made of 100% multifilament yarn

- Densely woven barrier fabric

Material : 168G Series

| Material | 98% Polyester Filament with Conductive Carbon Compound Filament Yarn (E.C.F) |

| Weave | 3/2 Twill Woven With E.C.F At 5mm Grid |

| Weight | 120g/m2 |

| Colour | White, Dark Blue, Light Blue & Green |

| Density | WARP : 83 threads/cm WEFT : 47 threads/cm |

| Base Yarn | WARP : 75 denier/72f WEFT : 75 denier/72f |

| Surface Resistance | 108Ω – 109Ω ANSI/ESD 11.11 |

| Air Permeability | 3.19cfm ASTM D737 1.9c.c/cm2/sec JIS LI1096 |

| Decay Time | ± 0.01 second NFPA – 99 |

| Filteration Efficiency | 0.3 µM : 97.5% 0.5 µM : 97.5% SEIREN METHOD |

| Tearing Strength | WARP : 2.85kg WEFT : 1.93kg ASTM D1424 |

| Tensile Strength | WARP : 121.7kg WEFT : 65.6kg ASTM D 5034 |

| Friction Charges Electrostatic Potential | WARP : 2V WEFT : 2V JIS LI1094 – B (BEFORE WASH) |

Material : 133G Series

| Material | 100% Polyester Fabric with Conductive Carbon Compound Filament Yarn (E.C.F) |

| Weave | 2/1 Twill Woven With E.C.F At 5mm Grid |

| Weight | 100g/m2 ± 5% |

| Colour | White, Dark Blue, Light Blue, Light Green, Yellow & Pink |

| Density | WARP : 176 threads/inch WEFT : 99 threads/inch |

| Base Yarn | WARP : 75 denier/36f WEFT : 75 denier/72f |

| E.C.F | WARP : 72 denier/30f WEFT : 75 denier/72f |

| Surface Resistance | 106Ω – 108Ω ANSI/ESD 11.11 |

| Air Permeability | : 5.0 c.c/cm2/sec JIS LI1096 – A – 1990 |

| Decay Time | ± 0.01 second NFPA – 99 |

| Filteration Efficiency | 0.5 µM : > 65% SEIREN METHOD |

| Tearing Strength | WARP : 2.245kg WEFT : 1.525kg JIS LI1096 – 6.12.5 – D |

| Tensile Strength | WARP : 100kg WEFT : 55.1kg JIS LI1096 – 6.12 – 1A |

| Friction Charges Electrostatic Potential | > 50V JIS LI1094 – B |